Quote

Subtotal: $0

Product Description

•Imported high speed commutator motor,small cubage and strong suction.

•Connection between operation controller and electric control box free and convenient operation.

•Controlled by microcomputer,action precision.

•Out hanged air storage device to thoroughly clean the dust on the strainer.

•Electronic action detector and low fault rate.

•Multi fault indicator lamp to facilitate the customer knowing the reason and handling in time.

Specifications:

| Model | SAL-300C | SAL-360 | SAL-360E | SAL-400 |

|---|---|---|---|---|

| Motor (kW) | 1.1 | 1.1 | 1.1 | 0.75 |

| Conveying Capacity (kg/hr) | 250 | 300 | 300 | 350 |

| Conveying Height (m) | 4.5 | 4.5 | 4.5 | 4.5 |

| Material Hopper Volume (L) | 6 | 12 | 12 | 12 |

| Conveying Tube Calibre (mm) | 38 | 38 | 38 | 38 |

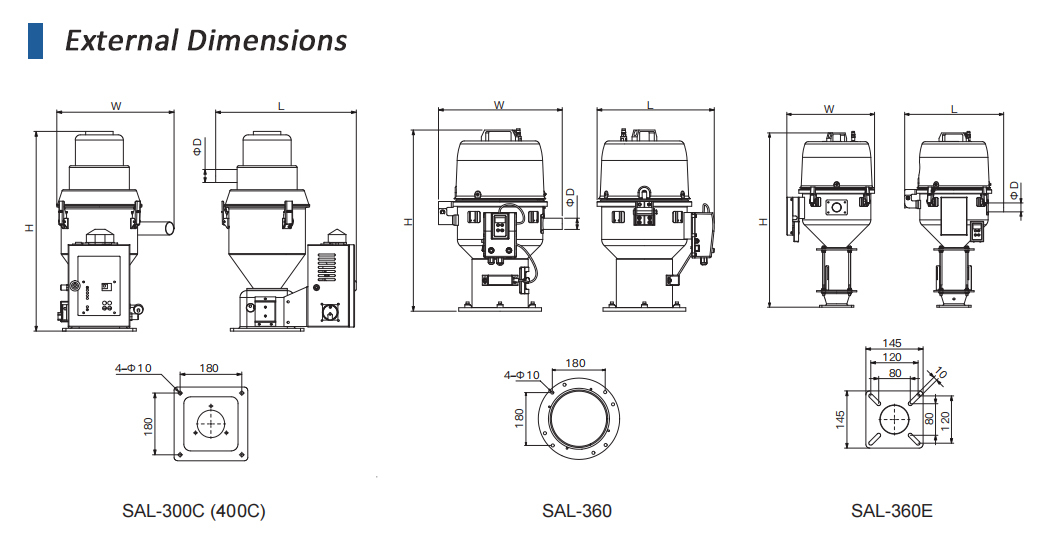

| L (mm) | 360 | 370 | 370 | 360 |

| W (mm) | 350 | 420 | 420 | 560 |

| H (mm) | 600 | 610 | 730 | 700 |

| Weight (kg) | 18 | 16 | 18 | 29 |

※We reserve the right to change specifications without prior notice.

Structures:

| 1 | Hex socket screwsM5×25 | 23 | Snap springφ8 |

| 2 | 5” Alu made handle | 24 | M6 Hexagonal socket nut |

| 3 | M5flat gasket | 25 | M6×16 Cross recessed pan head screw combination |

| 4 | M5pad | 26 | Electric cabinet assembly |

| 5 | Motor salver | 27 | The microcomputer manual controller assembly |

| 6 | Cross recessed pan head screw M5×12 | 28 | Suction tube rubber mat |

| 7 | Socket head cap screw combination | 29 | Suction tube |

| 8 | The fixed plate of Motor | 30 | Hexagonal nut lockingM4 |

| 9 | Sponge tape | 31 | Reed switch |

| 10 | Pressure switch | 32 | Hex socket screwsM6×10 |

| 11 | Air pipe | 33 | M6Flat washer |

| 12 | Inverse washing pipe assembly | 34 | Housing of reed switch |

| 13 | Air pipe contact | 35 | Ventilated window |

| 14 | Carbon brush type of Motor | 36 | Plum blossom handleM6×16 |

| 15 | Small countersunk head riveted nutsM6 | 37 | Blanking mouth assembly |

| 16 | Hopper cover compound | 38 | Cross pan head M3×45 |

| 17 | Filter cloth assembly | 39 | Diameter3mm gasket |

| 18 | Cross recessed pan head screwM4×12 | 40 | Locknut(Hex nutM3) |

| 19 | Hopper group welding | 41 | M6×20Hex socket screws combination |

| 20 | Front hinge | 42 | Lock block |

| 21 | Below hinge | 43 | Sponge tape |

| 22 | The hinge pin | 44 | Base flanged |