•Separation design between the controller and the material hopper,which is convenient and simple to operate.

•Controlled by microcomputer,action precision and alarm attentions.

•Motor overload protection equipped to effectively prolong the service life of the motor.

•With the high voltage blower, the materials can be conveyed in a long distance.

•The hopper is made from the stainless steel to ensure that the material can not be polluted.

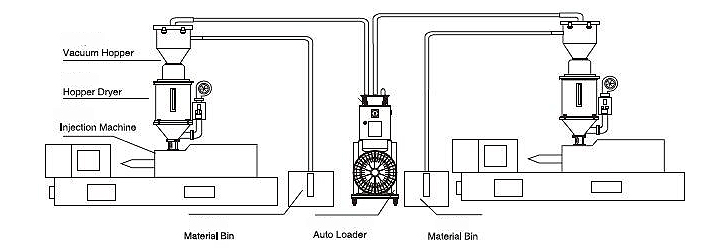

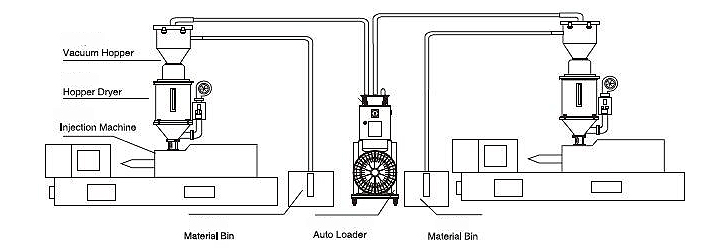

•The machine type one-to-several plastic injecting molding machine can be selected for charging as per customer's needs.

•The electric eye hopper or vacuum hopper can be selected according to customer's needs.

Specifications:

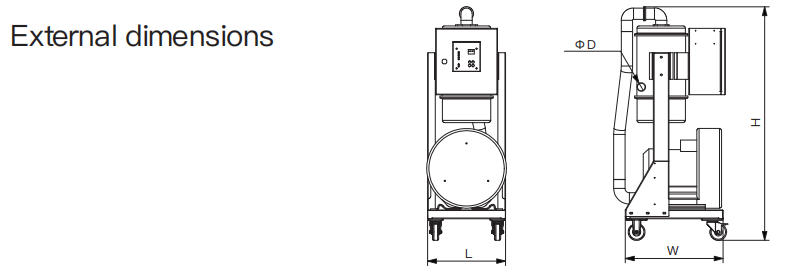

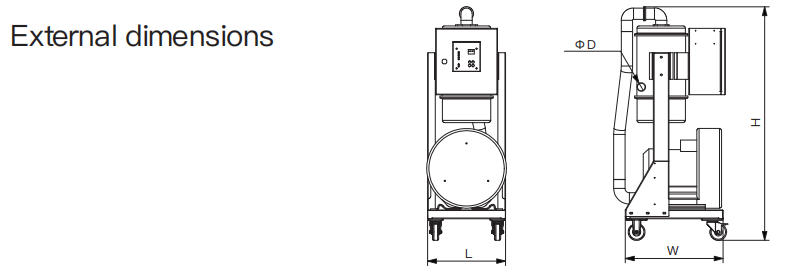

| MODEL | MOTOR (KW) | CONVEYING CAPACITY (KG/HR) | CONVEYING HEIGHT (M) | MATERIAL HOPPER VOLUM E(L) | CONVEYING TUBE CALIBRE (MM) | CONTROLLER LxWxH(MM) | Weight(kg) |

| SAL-3HP(F)E | 2.2 | 550 | 7 | 12L (12Lx2) | 38 | 355x440x1060 | 67 |

| SAL-4HP(F)E | 3 | 600 | 8 | 12L (12Lx2) | 38 | 355x440x1060 | 77 |

| SAL-5HP(F)E | 4 | 700 | 8 | 20L (20Lx2) | 51 | 405x560x1220 | 700 |

| SAL-7.5HP(F)E | 5 | 800 | 10 | 20L (20Lx2) | 51 | 405x560x1300 | 124 |

| SAL-10HP(F)E | 7.5 | 1000 | 12 | 20L (20Lx2) | 51 | 405x560x1300 | 126 |

※We reserve the right to change specifications without prior notice.

Installation diagram: